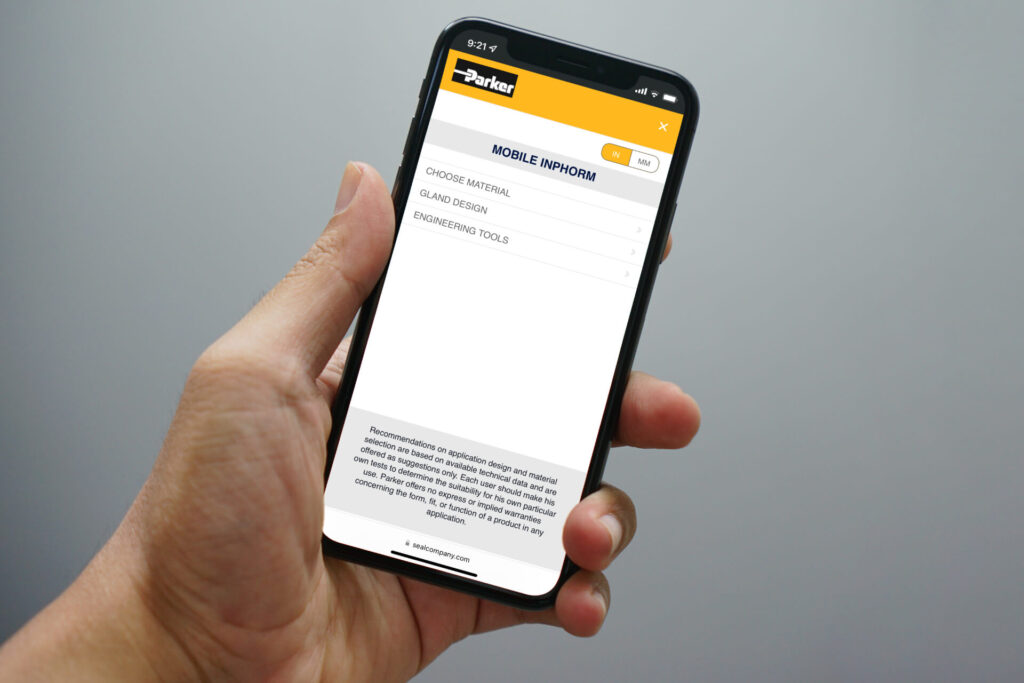

O-Ring Design Procedure using Mobile inPHorm.

The Mobile inPHorm tool is invaluable for finding the appropriate o-ring for your application. In addition to your personal computer, the web-based inPHorm also works on your tablet or mobile phone. On the opening screen, you will see three options. Select between material, gland design, or engineering tools.

The material option gives you multiple choices for selecting a Parker compound. These include fluid compatibility, ul listings, food and water, medical, and military specifications. You can also select a compound directly if you already know what you are looking for.

The gland design option helps you determine the appropriate gland dimensions depending on the standard type gland that you use.

Lastly, the engineering tools option has a table of limits for extrusion and a tool for troubleshooting leakage issues in an existing gland.

After you have selected your material and designed your gland, Parker’s web-based inPHorm generates a report summarizing your results. You can then instruct the program to email the report to the address of your choice. For more information, please visit www.parkerorings.com.

Parker's Design Tool & O-Ring Calculator

Recommended Manual Design Procedure

1. Determine the gland design for best sealing results.

(a) If the fluid medium or its specification is known, refer to the Fluid Compatibility Tables in Section VII or to the various material or other specifications listed in Section VIII.

(b) If the compound specification is known, refer to Table 8-2, Table 8-3 or Table 8-4 in Section VIII as applicable.

2. Find the recommended O-ring size and gland dimensions in the appropriate design table in Static O-Ring Sealing or Dynamic O-Ring Sealing, Sections IV and V, respectively.

3. For industrial use, order the O-ring by the Parker compound number followed by the size number.

Example: N0674-70 2-325

4. For a design problem that cannot be resolved using the information in the software, contact Seal Company for problem analysis and design recommendations.

When ordering parts made with a military, AMS, or NAS specification material, see the Aerospace reference guide.

Example: M82745-325